This guide has been produced to understand why the scheduling error, conflicting constraints, arise and methods to fix the problem.

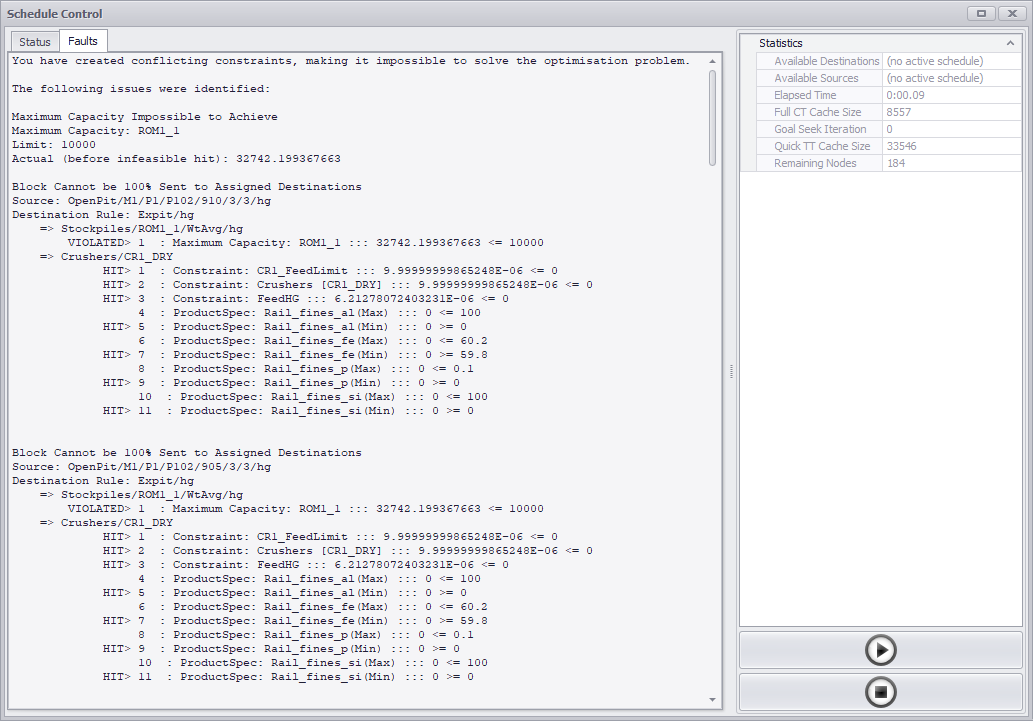

Figure 1 - Scheduling Error - Conflicting Constraints

The above optimization problem cannot be solved due to conflicting constraints. In Optimize Products mode as the scheduling engine operates in two passes:

- Selecting a block sequence based on target tonnes/rates

- Running an optimization to allocate each block to a destination.

If constraints, capacities, or product limits prevent material from being assigned to a destination, an optimization failure occurs. Use the following keywords to see which optimization parameter could not be met:

- VIOLATED indicates a capacity limit was exceeded.

- HIT means a product specification reached its limit.

Another method is providing an extra location for material to move when a certain constraint has been violated or hit. An overflow destination can be created to help investigate deeper the error message.

Want to learn more?

Online Help Manuals - Click here for the latest version

Learning Management System - Click here to login or here to request access

Comments

0 comments

Please sign in to leave a comment.